Dispelling a Common Engineering Myth: Does Reducing Voltage Increase Current?

Dispelling the myth: does reducing voltage increase current?

Voltage optimisation is a well-established solution for UK businesses looking to reduce energy consumption and improve efficiency. Yet a common question still arises from engineers and decision-makers alike: if you reduce voltage, won’t current go up?

The short answer is no, not in a way that increases your energy bill.

Let’s break down where this confusion comes from and why voltage optimisation continues to deliver proven savings across commercial and industrial settings.

Understanding the relationship between voltage and current

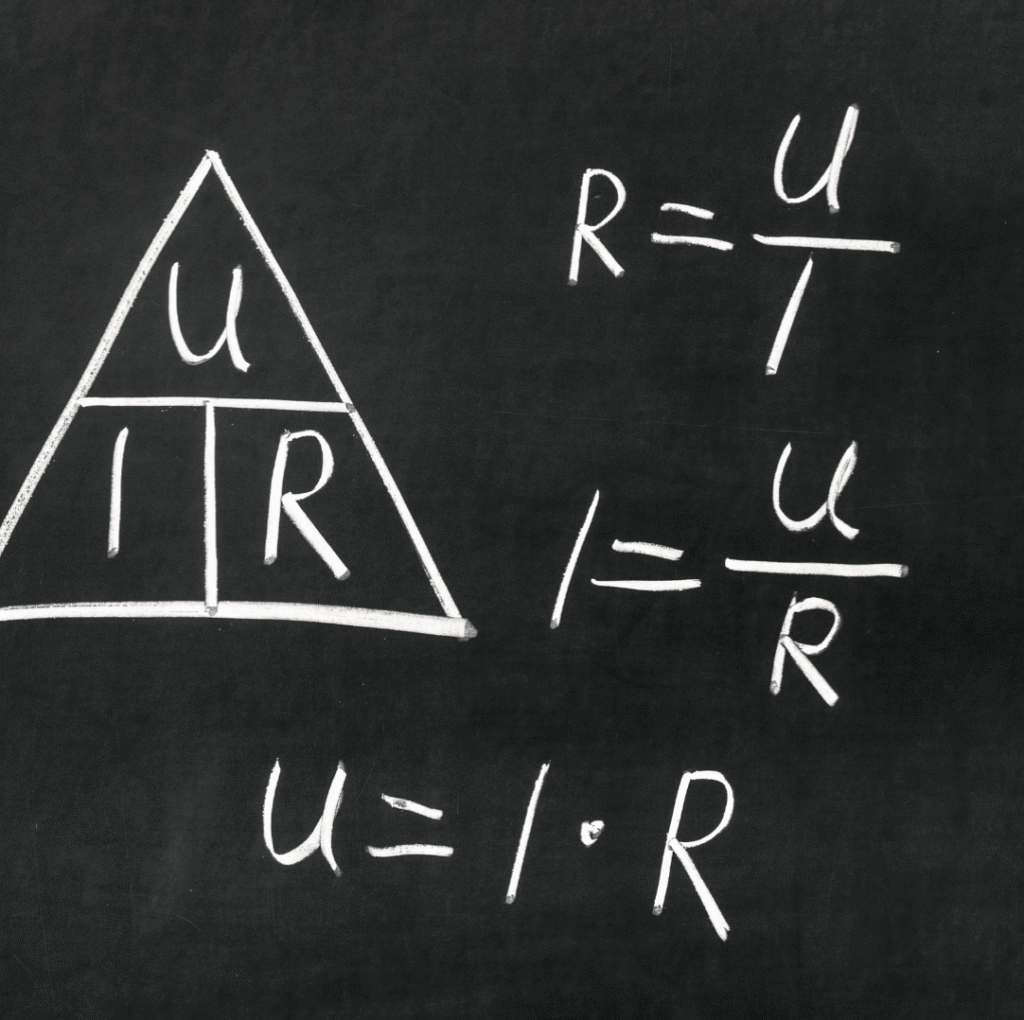

At the heart of this debate is Ohm’s Law, which defines the relationship between voltage (V), current (I), and resistance (R):

V = I × R

Resistance is a constant value determined by the physical construction of your electrical equipment. It does not change when voltage changes.

So, if voltage decreases and resistance stays the same, current must also decrease. This is what happens in the case of most resistive loads like incandescent lights and heaters. Lowering the voltage leads to a drop in current and therefore in power consumption.

Where the voltage misconception comes from

Some engineers assume that power (P = V × I) needs to remain constant, and therefore when voltage drops, current must increase to keep power steady. This would be true if the load were designed to draw constant wattage, but most of the time, this is not the case.

In reality, most electrical devices respond to a drop in voltage with a proportional drop in current, especially resistive loads. Power only stays constant in devices specifically designed to do so, such as switch-mode power supplies.

Voltage optimisation and different equipment types

Let’s look at how voltage reduction affects common types of electrical loads:

Resistive loads

Examples: incandescent lights, electric heaters

These loads have a fixed resistance. When voltage drops, current drops too. This results in reduced power consumption and lower energy bills.

Inductive loads

Examples: motors, transformers

These are more complex. Motors may draw slightly more current to maintain torque, but in most cases, the voltage reduction brings the motor closer to its design voltage. This improves efficiency and reduces heat build-up. Any increase in current is usually minimal and does not raise energy costs. Overall consumption remains steady or improves.

Constant wattage devices

Examples: switch-mode power supplies (used in IT equipment)

These systems are designed to maintain output wattage. If voltage drops, current increases to compensate. But here’s the key point: this does not increase your energy consumption measured in kilowatt-hours. It just shifts how the same amount of energy is delivered.

Why voltage optimisation makes business sense

Reducing voltage to match what your equipment actually needs lowers energy waste. Most UK sites are supplied with voltages higher than necessary. Your equipment is likely rated for 220V, but your site could be receiving 240V or more. That 10 to 15 percent excess turns into wasted electricity, heat, and maintenance issues.

Voltage optimisation solves this by stepping down incoming voltage to a more suitable level. This reduces wear and tear, improves equipment lifespan, and cuts unnecessary energy usage.

The impact of voltage optimisation in real settings

In commercial and industrial environments, motors, HVAC systems, refrigeration units and lighting often account for the majority of energy use. These systems typically perform better and more efficiently when operating at or close to their design voltage.

For example, a motor supplied with 240V when it is designed for 220V will run hotter and wear out faster. Reducing the supply to 220V reduces thermal stress, extends motor life, and lowers your electricity bills.

These real-world results are why so many businesses are now integrating voltage optimisation into their energy strategy.

Key points to remember about voltage and current

Lowering voltage for resistive loads reduces both current and power

In most inductive and motor-based loads, energy use does not increase

Switch-mode supplies maintain constant power but do not increase overall energy use

Power at the fiscal meter drops in most cases, leading to measurable savings

Conclusion: voltage optimisation works when understood properly

The idea that reducing voltage increases current in a way that negates savings is a misunderstanding of basic electrical principles. In most real-world applications, voltage optimisation reduces both energy use and operating costs.

For UK businesses focused on energy efficiency and sustainability, voltage optimisation is not just a quick win. It is a smart, long-term strategy that reduces costs and improves equipment performance without disrupting operations.

With the right installation and equipment survey, businesses can confidently reduce their energy use, extend equipment lifespan, and move closer to their carbon goals. Voltage optimisation remains one of the most effective tools to achieve this.